Now: Front And Backside Macro Defect Inspection In One Versatile, Super-Fast Tool

New EAGLEview 6 with BSI Backside Inspection

In recent years, the demand for backside semiconductor wafer inspection has increased dramatically. Especially for certain devices, backside defects like scratches, particles, resist problems, etc. can significantly impact device quality…

Now, Microtronic has developed an elegant solution: new EAGLEview 6 is able to deliver macro defect semiconductor wafer inspection on both the top and backside of wafers, quickly and efficiently, on a single tool.

A uniquely efficient system design provides two high-performance semiconductor wafer imagers: one for the topside and one for the backside. So the semiconductor wafer does not need to be turned over – which simplifies and speeds the inspection cycle.

Also, having dual capabilities in a single tool means you don’t need to buy a second system for backside inspection. Which reduces your expense and conserves floor space. And because of its unique high-speed design, EAGLEview 6 can actually inspect both semiconductor wafer sides almost as quickly as a single side. So, while it’s gathering twice as much defect data, its throughput is only minimally affected.

Powerful ProcessGuard™ software correlates front and backside defect information

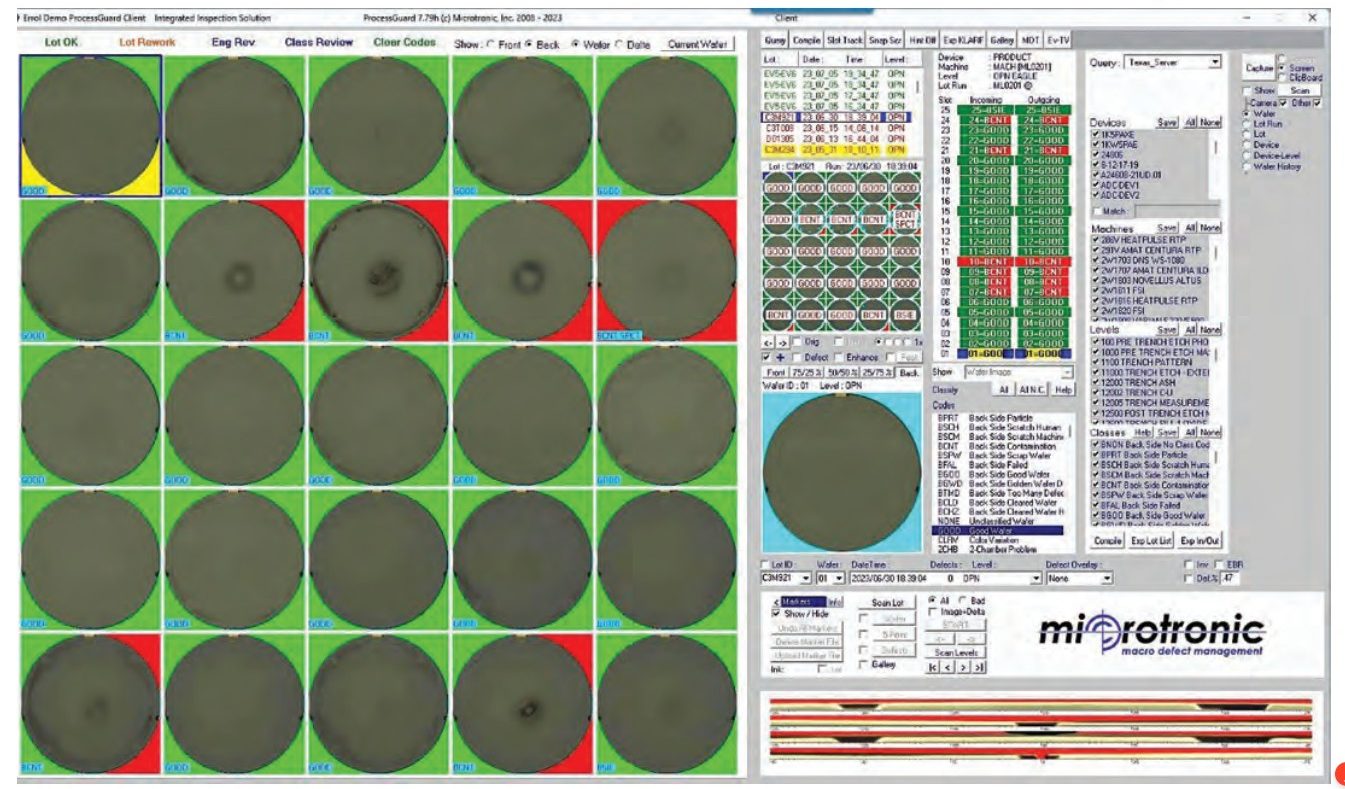

Backside inspection (BSI) is seamlessly integrated into Microtronic’s powerful ProcessGuard software. It provides the same functionality for backside images as frontside images, including Zoom, Scan, Lot, etc.

ProcessGuard also integrates and correlates front and backside images so it can show front, back and front/back composite images. Plus, a yellow crosshair can show the identical position on both sides of the wafer. In addition, the same position can be displayed for the reference wafer while the Delta Image shows the difference between the current and reference wafer.

The backside inspection option can be ordered on new EAGLEview 6 tools and also can be field retrofitted for existing EAGLEview tools.

EAGLEview inspects 100% of every wafer – front and back

One major EAGLEview advantage is its ultra-high speed: over 3000 wafers/day. This enables it to macro-inspect 100% of every wafer, front and back, edge to edge, in every lot. By comparison, most other tools can only sample a small area on a small number of wafers per batch.

But with its high speed, EAGLEview can see a great deal more – and see it earlier in the overall process. This lets you take care of any needed rework earlier, which reduces your scrap. And it lets far fewer semiconductor defects get through to become end-product quality problems.

ProcessGuard Software: Backside Macro Defect Information for Every Wafer

For more on backside wafer inspection, contact us at [email protected]. Be sure to subscribe to our tech bulletins to stay informed on all our latest developments.

This website uses cookies and other tracking technologies to gather information about you, your device, and how you interact with this website to better understand how visitors use the site and to offer you a more personalized experience. We may share information about your use of this site with our social media, marketing, security and analytics partners. By continuing to use this website, you agree to these practices. For more information, please see our Privacy Notice.

Select “Accept All” to allow all of these technologies and uses or “Required Only” to limit ones that are not essential. If you select “Required Only” it only applies to this website, and only to the browser and device you are using at the time you make the selection. If you clear cookies on your browser, you will need to make your selection again.

The GPC signal is honored.

Now: Front And Backside Macro Defect Inspection In One Versatile, Super-Fast Tool

(Download PDF)

Now: Front And Backside Macro Defect Inspection In One Versatile, Super-Fast Tool

New EAGLEview 6 with BSI Backside Inspection

In recent years, the demand for backside semiconductor wafer inspection has increased dramatically. Especially for certain devices, backside defects like scratches, particles, resist problems, etc. can significantly impact device quality…

Now, Microtronic has developed an elegant solution: new EAGLEview 6 is able to deliver macro defect semiconductor wafer inspection on both the top and backside of wafers, quickly and efficiently, on a single tool.

A uniquely efficient system design provides two high-performance semiconductor wafer imagers: one for the topside and one for the backside. So the semiconductor wafer does not need to be turned over – which simplifies and speeds the inspection cycle.

Also, having dual capabilities in a single tool means you don’t need to buy a second system for backside inspection. Which reduces your expense and conserves floor space. And because of its unique high-speed design, EAGLEview 6 can actually inspect both semiconductor wafer sides almost as quickly as a single side. So, while it’s gathering twice as much defect data, its throughput is only minimally affected.

Powerful ProcessGuard™ software correlates front and backside defect information

Backside inspection (BSI) is seamlessly integrated into Microtronic’s powerful ProcessGuard software. It provides the same functionality for backside images as frontside images, including Zoom, Scan, Lot, etc.

ProcessGuard also integrates and correlates front and backside images so it can show front, back and front/back composite images. Plus, a yellow crosshair can show the identical position on both sides of the wafer. In addition, the same position can be displayed for the reference wafer while the Delta Image shows the difference between the current and reference wafer.

The backside inspection option can be ordered on new EAGLEview 6 tools and also can be field retrofitted for existing EAGLEview tools.

EAGLEview inspects 100% of every wafer – front and back

One major EAGLEview advantage is its ultra-high speed: over 3000 wafers/day. This enables it to macro-inspect 100% of every wafer, front and back, edge to edge, in every lot. By comparison, most other tools can only sample a small area on a small number of wafers per batch.

But with its high speed, EAGLEview can see a great deal more – and see it earlier in the overall process. This lets you take care of any needed rework earlier, which reduces your scrap. And it lets far fewer semiconductor defects get through to become end-product quality problems.

ProcessGuard Software: Backside Macro Defect Information for Every Wafer

For more on backside wafer inspection, contact us at [email protected]. Be sure to subscribe to our tech bulletins to stay informed on all our latest developments.

Download Microtronic Macro Defect Brochure

Microtronic Overview Video

Navigation

Share on Social Media