Now you can weigh wafers at the same time you’re inspecting for macro defects.

Versatile EAGLEview 6 macro defect inspection can add WaferWeight for enhanced production control

Not all wafer production problems can be detected visually or electrically. Some can only be caught by tracking changes in semiconductor wafer mass that occur during processing – especially in deposition, etch, plating, backgrinding, bonding, TSV, and similar steps. To date, however, semiconductor wafer weight measurement methods have been slow and expensive, requiring a separate tool…

Now, Microtronic’s patented WaferWeight gives fabs a way to track semiconductor wafer mass quickly, accurately, and economically – concurrently with semiconductor macro defect inspection, all on one tool: the Microtronic EAGLEview™. WaferWeight can be added to the newest EAGLEview 6 and also to previous models.

The advanced WaferWeight capability is being used by many top-tier fabs around the world.

High system speed makes it viable

In order to accurately and comprehensively monitor changes in semiconductor wafer weight, it’s important for fabs to get data from every wafer in every lot. EAGLEview’s unique high speed makes that possible. This versatile tool can macro-inspect the frontside and backside and also weigh every single wafer in every lot. By comparison, most other inspection tools can only sample a small area on a small number of wafers per batch.

High-resolution wafer weight data – in a powerfully informative database

WaferWeight measurements offer a resolution as low as 0.1mg, enabling precise tracking of wafer mass changes between process steps and across different wafers in a lot. Any weight change exceeding allowable ranges can immediately flag an issue requiring further inspection or correction.

Weight data is stored in EAGLEview’s powerful ProcessGuard™ software, providing detailed information on every wafer processed – organized by lot, date, and time. The system can also automatically randomize wafers and track incoming and outgoing slot positions for each wafer.

Tracking pre/post processing wafer weights – to see lot-to-lot differences

Integrated slot-positional analysis – to see wafer-to-wafer differences

The highly-informative Slot Track tool

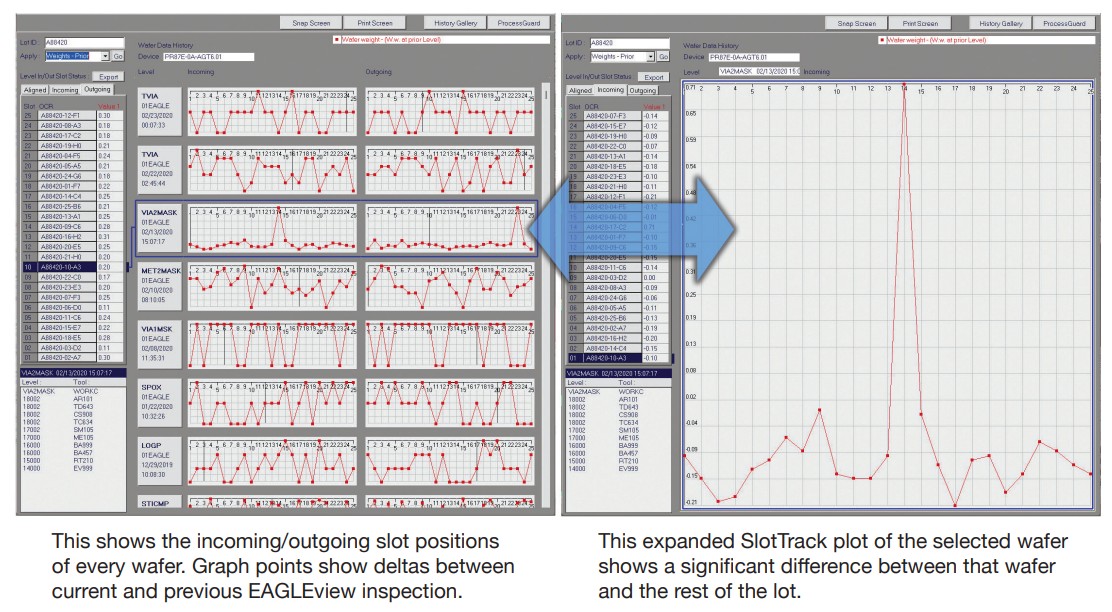

As the above example shows, EAGLEview’s powerful ProcessGuard software integrates proprietary SlotTrack analysis – which can automatically randomize wafers and track the incoming and outgoing slot positions of every wafer.

SlotTrack can automatically record the slot positions of every semiconductor wafer in every EAGLEview inspection and correlate them with various types of data – such as electrical test parameters, multiprobe bin results, defect density, and more. With WaferWeight monitoring, SlotTrack will plot each wafer’s weight and pre/post processing deltas by slot position, which can quickly signal wafer-to-wafer differences.

EAGLEview 6: the industry’s fastest and most versatile macro defect inspection tool

– now incorporating WaferWeight

EAGLEview delivers an unparalleled macro defect inspection speed, which enables it to examine 100% of every semiconductor wafer in every lot, rather than just sampling small areas on a small number of wafers per batch as other tools do.

This unique system – now including WaferWeight – enables fabs to see a great deal more, earlier in the overall process. This allows any needed rework to be done sooner, reducing scrap and permitting fewer defects to get through to become end-product quality problems.

To get more details about EAGLEview 6 or WaferWeight email us at [email protected]. Subscribe to our tech bulletins to stay informed on our latest advances.

This website uses cookies and other tracking technologies to gather information about you, your device, and how you interact with this website to better understand how visitors use the site and to offer you a more personalized experience. We may share information about your use of this site with our social media, marketing, security and analytics partners. By continuing to use this website, you agree to these practices. For more information, please see our Privacy Notice.

Select “Accept All” to allow all of these technologies and uses or “Required Only” to limit ones that are not essential. If you select “Required Only” it only applies to this website, and only to the browser and device you are using at the time you make the selection. If you clear cookies on your browser, you will need to make your selection again.

The GPC signal is honored.

Now You Can Weigh Wafers While Inspecting for Macro Defects

(Download PDF)

Now you can weigh wafers at the same time you’re inspecting for macro defects.

Versatile EAGLEview 6 macro defect inspection can add WaferWeight for enhanced production control

Not all wafer production problems can be detected visually or electrically. Some can only be caught by tracking changes in semiconductor wafer mass that occur during processing – especially in deposition, etch, plating, backgrinding, bonding, TSV, and similar steps. To date, however, semiconductor wafer weight measurement methods have been slow and expensive, requiring a separate tool…

Now, Microtronic’s patented WaferWeight gives fabs a way to track semiconductor wafer mass quickly, accurately, and economically – concurrently with semiconductor macro defect inspection, all on one tool: the Microtronic EAGLEview™. WaferWeight can be added to the newest EAGLEview 6 and also to previous models.

The advanced WaferWeight capability is being used by many top-tier fabs around the world.

High system speed makes it viable

In order to accurately and comprehensively monitor changes in semiconductor wafer weight, it’s important for fabs to get data from every wafer in every lot. EAGLEview’s unique high speed makes that possible. This versatile tool can macro-inspect the frontside and backside and also weigh every single wafer in every lot. By comparison, most other inspection tools can only sample a small area on a small number of wafers per batch.

High-resolution wafer weight data – in a powerfully informative database

WaferWeight measurements offer a resolution as low as 0.1mg, enabling precise tracking of wafer mass changes between process steps and across different wafers in a lot. Any weight change exceeding allowable ranges can immediately flag an issue requiring further inspection or correction.

Weight data is stored in EAGLEview’s powerful ProcessGuard™ software, providing detailed information on every wafer processed – organized by lot, date, and time. The system can also automatically randomize wafers and track incoming and outgoing slot positions for each wafer.

Tracking pre/post processing wafer weights – to see lot-to-lot differences

Integrated slot-positional analysis – to see wafer-to-wafer differences

The highly-informative Slot Track tool

As the above example shows, EAGLEview’s powerful ProcessGuard software integrates proprietary SlotTrack analysis – which can automatically randomize wafers and track the incoming and outgoing slot positions of every wafer.

SlotTrack can automatically record the slot positions of every semiconductor wafer in every EAGLEview inspection and correlate them with various types of data – such as electrical test parameters, multiprobe bin results, defect density, and more. With WaferWeight monitoring, SlotTrack will plot each wafer’s weight and pre/post processing deltas by slot position, which can quickly signal wafer-to-wafer differences.

EAGLEview 6: the industry’s fastest and most versatile macro defect inspection tool

– now incorporating WaferWeight

EAGLEview delivers an unparalleled macro defect inspection speed, which enables it to examine 100% of every semiconductor wafer in every lot, rather than just sampling small areas on a small number of wafers per batch as other tools do.

This unique system – now including WaferWeight – enables fabs to see a great deal more, earlier in the overall process. This allows any needed rework to be done sooner, reducing scrap and permitting fewer defects to get through to become end-product quality problems.

To get more details about EAGLEview 6 or WaferWeight email us at [email protected]. Subscribe to our tech bulletins to stay informed on our latest advances.

Download Microtronic Macro Defect Brochure

Microtronic Overview Video

Navigation

Share on Social Media